Home » Bushings, rotors & vanes

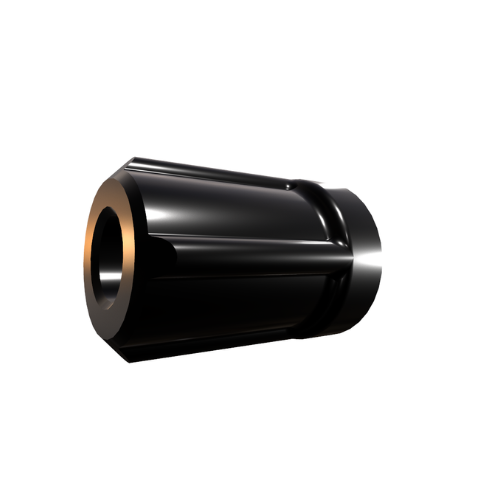

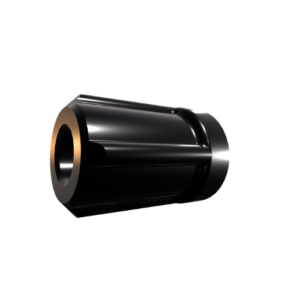

Bushings, Rotors & Vanes

Friction materials are used anywhere parts in contact (rotation or transferal) should not wear. The potential applications are endless. In the automotive industry we find friction application in:

- Bushings

- Rotor and vanes

Product Specifications

- Hardness

- Young modulus

- Strength

- Heat expansion

- Friction coefficient

- Capability to mold shapes

- Dimensions and precision

- Temperature stability

- Chemical resistance

- Weight

- 4 years of development: material knowledge, plastic coumpounding experience, molding, and injection expertise

- High load % materials available in thermoplastic or thermoset

- Injectable solutions without machining

- Thermally stable products

- Oil less solutions

- Manufacturing capacities in India and China

- Development center in France (Amiens)

AVOCarbon developed exceptional moldable or injectable solutions in thermoset or thermoplastic that can be processed competitively and used in different applications:

ELECTRICAL VACUUM PUMPS (EVP) : Brake assistance for thermal, electric and hybrid vehicles

COMFORT MOTOR

WATER PUMP

FUEL PUMP

Based on your requirements, we will select the best grade and pressing technology to provide an innovative solution.

Based on your requirements, we will select the best grade and pressing technology to provide an innovative solution.

Related products

Assemblies

Assembly brush card is the part of the heart of the electric motor that integrate the actuator system for several applications.

Seals

The main function of the mechanical seal is to avoid leaks between the rotating machine (pump, agitator…) and its environment.

Brushes

The carbon brush function is to carry electric current from a stationary part to a moving part.

Chokes

Chokes and inductances are passive electronic components used in many applications to smooth out the current.